The Raritan Blog

Home » Raritan Blog

What a 55kW Rack Power Strip Looks Like

Henry Hsu

April 23, 2013

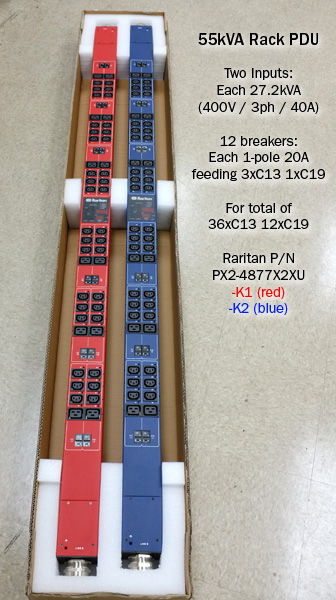

Last week, Raritan shipped our first production run of—what we believe to be—the highest-density rack power strip in the industry to date.

Like all other Raritan rack power strips sold in North America, these units are UL Listed (bear the true UL Listed Mark). They will be placed in cabinets that will obviously get very hot, so like all Raritan power strips with the part number prefix “PX2”, these units have a maximum ambient temperature of 140°F (60°C) in North American markets.

Although the customer application is confidential, generally speaking, this power strip could easily handle up to twelve blade chassis (with common configurations) in a Tier IV environment:

- The power strip provides 12 individual circuit breakers, each rated at 20A @ 230V. (It’s actually 240V, but in this client’s case they are running 230V).

- That means each breaker can handle a maximum of approximately 4500W (UL489 breakers on our power strips are fully rated, i.e., they can run at their full 20A specification and do not have to be “derated”.)

- This happens to coincide with real-world power draws of many common blade deployments such as HP c7000 or Cisco UCS 5100 series, etc. So each breaker could potentially support a single blade chassis each.**

**This is meant as a generalization. Please be sure to consult your Raritan power architect for more detailed provisioning guidance.

Today, the status quo for cabinet densities tends to be approximately 5 to 10 kW. Raritan has been very fortunate to have partnered with some of the industry’s most forward-thinking data center operators and architects—and have thus designed and deployed a significant number of different power strip configurations at higher densities. For electrical reasons, they cluster in the 14kW, 25kW, 28kW, 33kW, and now 55kW ranges.

It’s a great deal of fun, and I enjoy advising clients on the best way to deploy ever-increasing power densities at a minimal cost.

Here are some more photos, if you’d like to take a closer look:

- Same photo as above, in high-resolution;

- Top of PDU;

- Bottom of PDU;

Please note:

- This application employs a 1” trade size conduit, to provide input power from the RPP—which is why you do not see an input cord.

- We designed this with two 415V, 3-phase, 40A inputs on each power strip—in order to facilitate certain physical connectivity constraints. But the same electrical solution could have been provided with a single 415V, 3-phase, 80A input.

- Nerds may want to know that technically this is a 57.5kVA-rated power strip @ 415V/3phase, and 55.4kVA @ 400V/3phase. Also, while I use kVA and kW interchangeably in colloquial conversations; when consulting a client, I will more typically assume a modern power factor of approximately 97.5%—thus making this a ~56kW (415V) or 54kW (400V) power strip. But that would be an excessively long title for a blog post, so I just split the difference and call it “55kW”, nominally.

I am obligated by law to mention that this power strip happens to be from Raritan’s PX2-4000 Series—which means that in addition to supplying an absurd amount of power, it also provides billing-grade (+/- 1%) kWh energy metering for every inlet, breaker, and individual outlet [C13 and C19]. It is compatible with our wide variety of environmental sensors (temp, humidity, differential air pressure, leak, door open/close); Wi-Fi (802.11a/b/g/n) options; daisy-chaining; USB mass configuration; etc. And it can be queried via either SNMP v1/2c/3 or JSON-RPC.

But enough with the infomercial… fundamentally, I just think it’s awesome to have a single rack PDU that delivers the equivalent amount of power as consumed by five average U.S. homes.

Visit Us at AFCOM's Data Center World in Las Vegas – Learn and Maybe Even Win

Dorothy Ochs

April 19, 2013

Join us as we discuss how to successfully deploy high power to your racks, and full power chain and network connection management

Stop by our booth (#835) to see our newest Power, DCIM and KVM solutions

Get a registration discount on us—Use code RARITANS13 Register Now - http://www.datacenterworld.com/spring2013/

Deploying High Power at the Rack

Date: Tuesday, April 30 from 8:15 to 9:15 am

Room: Palm D

Speaker: David Wood - Director, Power Business at Raritan

Full Power Chain and Network Connection

Date: Wednesday, May 1 from10:00 to 11:00 am

Room: Banyan CD

Speaker: James Cerwinski - Manager, Project Management at Raritan

We will have live demos at our booth (#835) and will be raffling an iPad. Be sure to stop by!

Enough Data Center Management Ideas to Make Your Head Spin

Yee Liaw

April 18, 2013

I’ve been back from the Green Grid Forum 2013 for over a week now, but the insights I formed there are still making my head spin.

I’ve been back from the Green Grid Forum 2013 for over a week now, but the insights I formed there are still making my head spin.

Early on, the Green Grid was focused on keeping data centers cool. We all remember when walking into a data center was like stepping into a refrigerator. Now that is changing. Most IT equipment can now operate reliably at much higher temperatures. So this improved the PUE of data centers without having excessive cooling.

Now, in the age of Petabyte of data being processed, a key theme at the conference was resource efficiency among a huge array of compute equipment. To achieve this, we are all now focusing on more granular management. No more refrigerator approach. Now data center managers are looking for efficiencies down at the rack and device level. Take servers for instance.

Consumers of power in a server:

- Server processors

- Memory

- Discs or PCI slots

- The motherboard

- The fan

- Networking interconnects

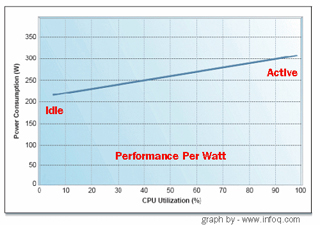

A Green Grid study that was of great interest to me focused on the power required for different CPU utilization in data center servers from an idle state to an active state. When this state changes, the jump in energy draw is dramatic.

The main difference in power consumption between an idle server and an active one is based on the spinning of the disc when the server must move the read-write head. The differential in power utilization from idle to active is about 30%. You can see that in the chart above.

CPU utilization studies have shown that many servers sit idle for large periods of time. But even in that idle state, they spin. And the chart above shows that they are still consuming a large amount of power. The Green Grid paper suggested segregating servers so that some development and build servers should be isolated and shut down completely when not in use. Backup servers are usually only needed at nighttime when the devices they’re backing up are idle. During the day, they could be shut down.

Another great example in the Green Grid presentation was a server farm running 10 servers that are utilized only 50% each on average (we suspect your utilization will be even less). Five servers utilized at 100% would be exponentially more energy efficient. The question is, how to understand what each of your servers is doing on a granular level.

How to gather granular data and manage your data center power

Power IQ is our energy management component of Raritan’s DCIM solution, and it helps your data center become dramatically more energy efficient. Here is a partial list of what this pro-active software solution can do:

- User configurable dashboard

- Agentless graceful shutdown of Windows®, Linux® and Unix® device groups

- A psychrometric chart to calculate possible energy savings from simply increasing temperature

- Energy cost bill-back reports driving behavior

- Decommission flags to forecast energy savings when eliminating servers

- Baseline consumption and changes of various energy saving initiatives

- Capture peak loads under compute stress to identify excess power capacity in the rack

- Power capacity forecast charts

- Power capacity utilization gauges

- Smart Rack View with Quick Charts

Looking through that list, you can see why Raritan is excited to be in the right place at the right time. We are leaders in intelligent power management for the data center thanks to our intelligent rack power distribution units and our powerful energy management software.

Click here to learn more about Raritan data center power management solutions

Deploying High Power at the Rack Webinar - April 25th

Dorothy Ochs

April 10, 2013

High-power requirements for data centers include racks filled with 1U “pizza box” servers or multiple blade server chassis in one rack. Network storage devices can also drive high demand for power.

Many data center managers are doing a good job conserving energy but, average power consumption at the rack may still go up. In fact, the increased efficiency means more power is available to support data center growth. This webinar will examine how to determine and design for peak actual power demand and the most efficient and reliable approaches for delivering power, especially when deploying blade servers.

Date: Thursday, April 25, 2013

Time: 11:00 AM ET

Register: https://www1.gotomeeting.com/register/829819449

3-phase, 50a to 60a 208V Power Strips (Rack PDUs) Demystified, Part II : Understanding Capacity

Henry Hsu

April 9, 2013

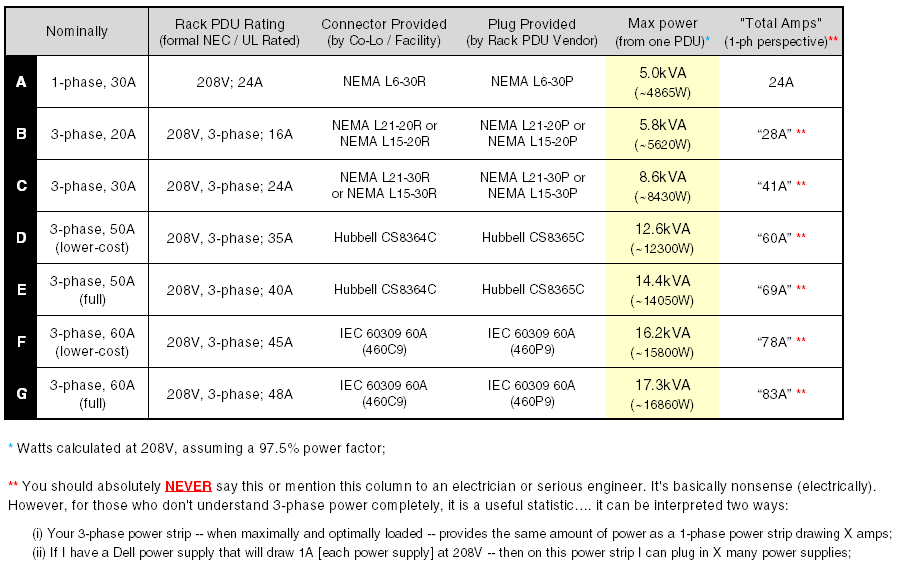

Despite the growing ubiquity of 3-phase power distribution (at 208V) in North American data centers, data center operators are still not sufficiently fluent with the real-world capacity implications of 3-phase power in their cabinets.

The principal reason is because—at 208V—the math required to understand 3-phase power distribution at the cabinet is completely counter-intuitive.

THE TWO MOST COMMON QUESTIONS I GET are some form of the following:

- On a single-phase power strip, I was able to power 10 servers. So how many will I be able to plug into this three-phase power strip? 30?

- I have a three-phase, 30A power strip. Does that mean I can have up to 30amps on each of the three phases of the power strip? That is, 90A total?

Whatever you think is reasonable in your head is, in fact, not actually the way it works. So the answer to both of the above questions is, “no”.

In a previous post, I attempted to explain at a lower-level the reasons why this is true—including a link to a very useful Excel spreadsheet to help you calculate 3-phase rack PDU loading and capacity planning.

But I realize that most people are like me (lazy). You don’t need to know the electrical rationale for the counter-intuitive math, you just need to know the answers! So in this post you will find just the main information you need to do simple capacity planning (without explaining the reasons why). I guess I really should have posted this first. Whoops!

THE SHORT VERSION: 2 Primary Tips

1. If you don’t totally, 100% understand 3-phase power distribution, it is best if you do NOT think or speak in terms of amps. In all likelihood, you will say something incorrect that confuses your electrician.

Instead, think about how many watts your equipment consumes, and how many watts your 3-phase power strip can provide. Watts are universally comparable, regardless of the supplied electrical configuration available at your rack: both your power strip manufacturer and your IT equipment vendor will tell you how many watts can be supplied. No matter what voltage you use; the rated current (amps); or whether you have 1-phase power or 3-phase power; etc… you can always compare watts.

If you absolutely must think using amps (i.e., “My Dell salesperson says this server will draw a maximum of 1.4A; and that’s all he will tell me.”), then I strongly suggest you: (a) download and use our 3-phase calculator here; and (b) consult the right-most column of the following cheat-sheet.

2. Print out this chart, pin it on your bulletin board ... and trust no other document on earth. (Click to view as high-resolution PDF).

SOME OBSERVATIONS

- This chart (and this blog post) applies ONLY to 208V, 3-phase power. If your facility utilizes 400V, 3-phase; or 415V, 3-phase power [i.e. most of EU, many other countries, and many of Raritan’s largest customers in North America]—then this information does not apply to you!!!

- Compare A and C in the chart above. Note that going from a single-phase (30A) power strip to a three-phase (30a) power strip does NOT get you 3x more power. That is a common misconception. Instead, you get 1.732x more power [the square root of 3]. Again, you will have to consult my previous post for an explanation why.

- Most rack PDU Manufacturers offer two versions of “50A, 3-phase” power strips—Options D and E in the chart above. In both cases, your co-location facility (or data center facility) provides a 50A, 3-phase input. But one power strip costs much less than the other. That is to say, moving from D to E increases the power strip’s costs materially, while offering only ~14% more power. That is why Rack PDU vendors often recommend Option D. EXCEPTION TO THE RULE: Most co-location customers [i.e., not owner/operator].

- Similarly, many rack PDU Manufacturers offer two versions of “60A, 3-phase” power strips—Options F and G in the chart above. This is less common but does occur on occasion.

THIS INFORMATION IS VENDOR NON-SPECIFIC

Please note that all the information in this post is not specific to Raritan power strips—but is vendor-agnostic… it’s just math. (Of course, if you do find this information beneficial, I sure would appreciate your considering Raritan as a potential provider for critical power distribution in your next build.)

Learn the most innovative features of rack power distribution units.

Subscribe

Upcoming Events

- Advancing Data Center Construction West 2024

- May 6 – 8 • Salt Lake City, UT

- Net Zero Data Center

- May 16 – 17 • Dallas, TX

- 7x24 Exchange Spring

- June 9th • JW Marriott Orlando Grande Lakes

Latest Raritan News

- Legrand Certifications and Process Controls Provide Confidence in Information Security for Network-Connected Devices in Data-Related Applications

- Posted on April 1, 2024

- Legrand Releases Version 4.0 of Raritan’s Industry-Leading Secure KVM Switches, Raising Bar for Secure Desktop Access

- Posted on July 31, 2023

- Legrand Revitalizes Data Center Sector with Two Revolutionary Intelligent Rack PDUs

- Posted on May 1, 2023

- Raritan Reveals The MasterConsole® Digital Dual KVM Switch

- Posted on February 18, 2021

- Legrand Data, Power and Control Division Announced as Finalist in Six Categories at DCS Awards 2020

- Posted on November 9, 2020